SENTIO – ROV simulation

SENTIO for SMD

Tree C is proud that Soil Machine Dynamics Ltd., a world leading manufacturer of remote intervention equipment, has been among the first to adopt Tree C’s technology as their synthetic environment and virtualization platform SENTIO.

The SENTIO Simulator suite comes with three SMD ROV models of varying sizes, various tools and equipment, as well as a range of interchangeable offshore training missions and scenarios. The simulator fully supports SMD’s control desk, and it therefore allows pilots to use realistic controls during training.

SENTIO for SMD

Tree C is proud that Soil Machine Dynamics Ltd., a world leading manufacturer of remote intervention equipment, has been among the first to adopt Tree C’s technology as their synthetic environment and virtualization platform SENTIO.

The SENTIO Simulator suite comes with three SMD ROV models of varying sizes, various tools and equipment, as well as a range of interchangeable offshore training missions and scenarios. The simulator fully supports SMD’s control desk, and it therefore allows pilots to use realistic controls during training.

SENTIO for SMD

Tree C is proud that Soil Machine Dynamics Ltd., a world leading manufacturer of remote intervention equipment, has been among the first to adopt Tree C’s technology as their synthetic environment and virtualization platform SENTIO.

The SENTIO Simulator suite comes with three SMD ROV models of varying sizes, various tools and equipment, as well as a range of interchangeable offshore training missions and scenarios. The simulator fully supports SMD’s control desk, and it therefore allows pilots to use realistic controls during training.

Specific Requirements?

Contact us to discuss your ROV simulation needs.

Increase asset efficiency

The subsea simulator is a platform for training, mission planning and engineering that improves the efficiency of your offshore operations.

By using the simulator you can train your pilots, plan your next offshore work or test that new equipment design you just created. The virtual environment allows you to test the limits of the whole subsea value chain. The simulator can be tailor-made to suit your needs with short lead time and high fidelity.

Increase asset efficiency

The subsea simulator is a platform for training, mission planning and engineering that improves the efficiency of your offshore operations.

By using the simulator you can train your pilots, plan your next offshore work or test that new equipment design you just created. The virtual environment allows you to test the limits of the whole subsea value chain. The simulator can be tailor-made to suit your needs with short lead time and high fidelity.

Increase asset efficiency

The subsea simulator is a platform for training, mission planning and engineering that improves the efficiency of your offshore operations.

By using the simulator you can train your pilots, plan your next offshore work or test that new equipment design you just created. The virtual environment allows you to test the limits of the whole subsea value chain. The simulator can be tailor-made to suit your needs with short lead time and high fidelity.

Create and configure

The simulator provides a wide range of training scenarios of varying scope and difficulty levels. The general setup of all scenarios consists of one of the three ROV models, which is connected to a TMS via a tether, which in turn is connected via an umbilical line to an A-Frame placed on the vessel deck.

All scenarios are built up from a large collection of virtual assets, which are part of the user’s asset library. The library can be expanded to include any type of simulated equipment.

All scenarios are fully configurable. Adjust the properties and positions of the assets that form the current scenario or completely overhaul the scene with new assets to create your own new scenario.

Create and configure

The simulator provides a wide range of training scenarios of varying scope and difficulty levels. The general setup of all scenarios consists of one of the three ROV models, which is connected to a TMS via a tether, which in turn is connected via an umbilical line to an A-Frame placed on the vessel deck.

All scenarios are built up from a large collection of virtual assets, which are part of the user’s asset library. The library can be expanded to include any type of simulated equipment.

All scenarios are fully configurable. Adjust the properties and positions of the assets that form the current scenario or completely overhaul the scene with new assets to create your own new scenario.

Create and configure

The simulator provides a wide range of training scenarios of varying scope and difficulty levels. The general setup of all scenarios consists of one of the three ROV models, which is connected to a TMS via a tether, which in turn is connected via an umbilical line to an A-Frame placed on the vessel deck.

All scenarios are built up from a large collection of virtual assets, which are part of the user’s asset library. The library can be expanded to include any type of simulated equipment.

All scenarios are fully configurable. Adjust the properties and positions of the assets that form the current scenario or completely overhaul the scene with new assets to create your own new scenario.

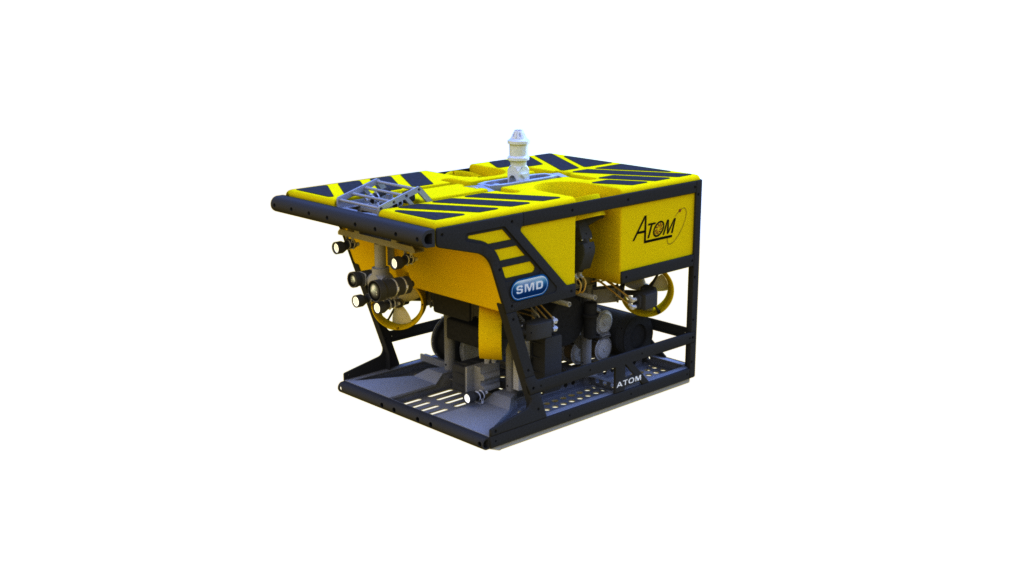

Work class ROVs

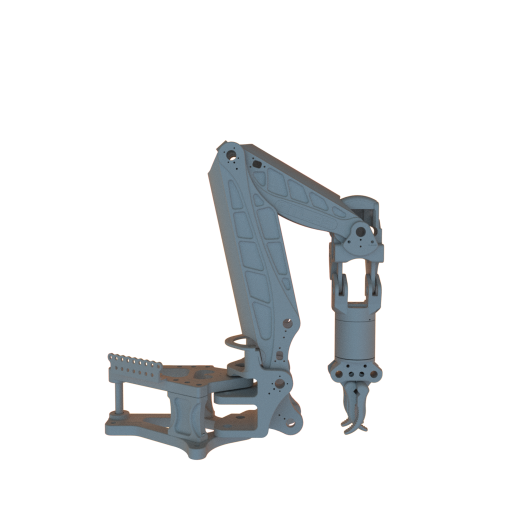

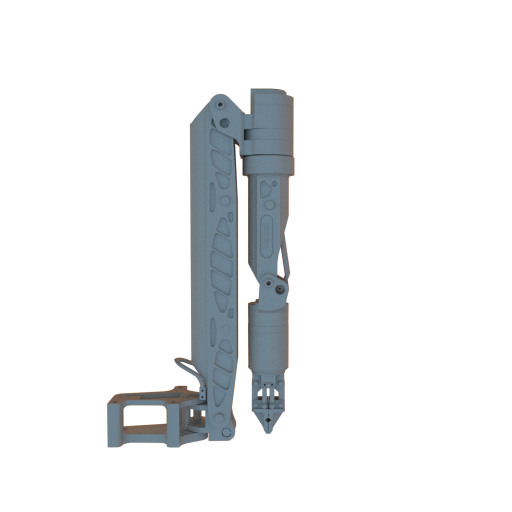

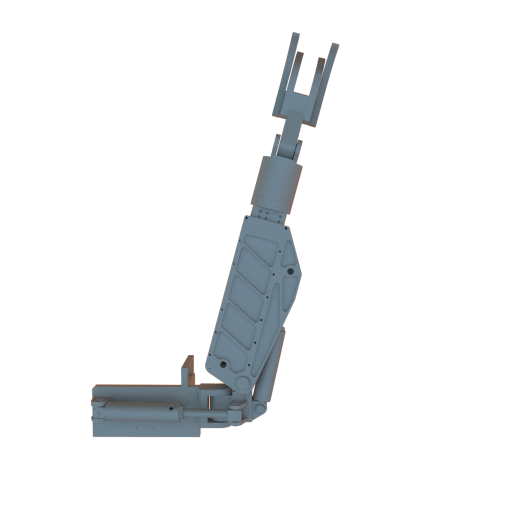

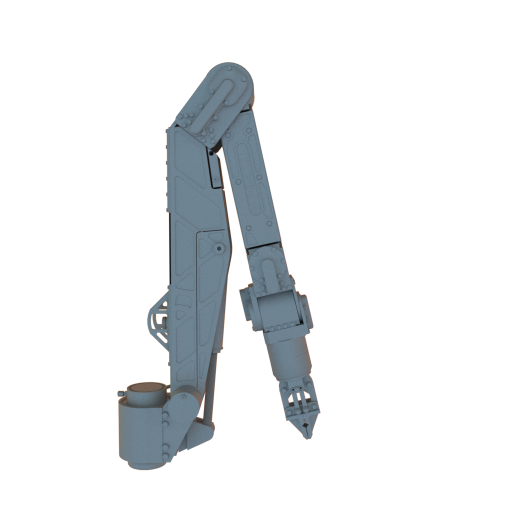

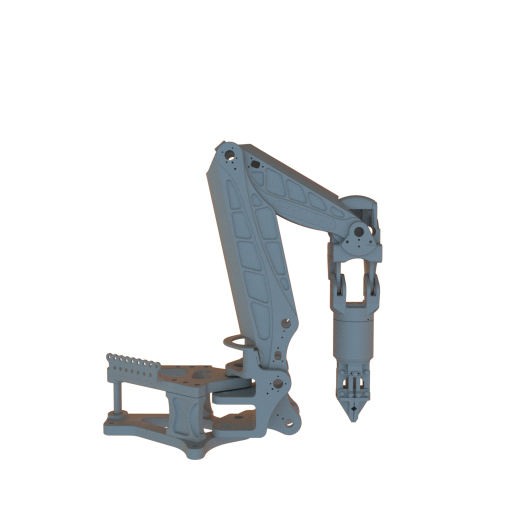

The simulator comes with a selection of simulated SMD work class ROVS, ranging from the lightweight ATOM to the heavy duty QUANTUM. Each ROV can be equipped with a selection of two of the five available manipulator arms, which are controlled by the ROV’s HCU. Furthermore the ROV frames and manipulator arms can interface with a variety of tools to supplement the scenario tasks.

ATOM

QUANTUM

QUASAR

ATLAS PARALLEL

ORION

RIGMASTER

TITAN-T4

ATLAS INTERMESHED

Cleaning Tools

Equip one of the Grinder brush, Grinder disc or Flexi clean tools to clean subsea structures from marine growth.

Dredging Tools

Equip one of the Zipjet tools to dredge the seabed and unearth buried equipment.

BOP interfacing Tools

With the Hotstab and Torque-tool the ROV can interface with the BOP to perform various tasks.

Scenario: BOP installation

The BOP installation scenario is a set of three different missions where the ROV pilot has to install a BOP (Blowout Preventer). In the first mission the pilot needs to place a seal on top of the Christmas tree pipe with the DV 7000 tool. The second mission consists of lowering the BOP above the Christmas tree and once it is in place, using the Torque Tool to fixate both structures. In the last mission, the Hot stab tool needs to be inserted in the BOP to pressurize the valves.

Scenario: BOP installation

The BOP installation scenario is a set of three different missions where the ROV pilot has to install a BOP (Blowout Preventer). In the first mission the pilot needs to place a seal on top of the Christmas tree pipe with the DV 7000 tool. The second mission consists of lowering the BOP above the Christmas tree and once it is in place, using the Torque Tool to fixate both structures. In the last mission, the Hot stab tool needs to be inserted in the BOP to pressurize the valves.

Scenario: BOP installation

The BOP installation scenario is a set of three different missions where the ROV pilot has to install a BOP (Blowout Preventer). In the first mission the pilot needs to place a seal on top of the Christmas tree pipe with the DV 7000 tool. The second mission consists of lowering the BOP above the Christmas tree and once it is in place, using the Torque Tool to fixate both structures. In the last mission, the Hot stab tool needs to be inserted in the BOP to pressurize the valves.

Scenario: Cable survey

The cable survey scenario provides the user with a mission to track a cable buried in the seafloor. The scenario lets pilots familiarize themselves with controlling and navigating using the TSS 440. The cable tracking system output is displayed in a dedicated interface.

Scenario: Cable survey

The cable survey scenario provides the user with a mission to track a cable buried in the seafloor. The scenario lets pilots familiarize themselves with controlling and navigating using the TSS 440. The cable tracking system output is displayed in a dedicated interface.

Scenario: Cable survey

The cable survey scenario provides the user with a mission to track a cable buried in the seafloor. The scenario lets pilots familiarize themselves with controlling and navigating using the TSS 440. The cable tracking system output is displayed in a dedicated interface.

Other scenarios

The simulator contains scenarios for several training purposes, like:

- Basic navigation

- BOP emergency intervention

- LARS launch and recovery

- Subsea jacket cleaning and inspection

- A treasure hunt and object retrieval

- Pipeline inspection

New specific scenarios can be added on request.

Other scenarios

The simulator contains scenarios for several training purposes, like:

- Basic navigation

- BOP emergency intervention

- LARS launch and recovery

- Subsea jacket cleaning and inspection

- A treasure hunt and object retrieval

- Pipeline inspection

New specific scenarios can be added on request.

Other scenarios

The simulator contains scenarios for several training purposes, like:

- Basic navigation

- BOP emergency intervention

- LARS launch and recovery

- Subsea jacket cleaning and inspection

- A treasure hunt and object retrieval

- Pipeline inspection

New specific scenarios can be added on request.

Connectivity and Scalability

The simulator is prepared to run on various hardware configurations, ranging from a laptop or pc up to a simulator connected to the actual control system console and/or a multi-display solution. Complementary views are offered to display the ROV CCTV cameras, sonar or survey. The 7 function manipulator can be controlled by means of a master arm controller. Optionally, the ROV operations can be performed using a dedicated joystick or xbox controller.

Connectivity and Scalability

The simulator is prepared to run on various hardware configurations, ranging from a laptop or pc up to a simulator connected to the actual control system console and/or a multi-display solution. Complementary views are offered to display the ROV CCTV cameras, sonar or survey. The 7 function manipulator can be controlled by means of a master arm controller. Optionally, the ROV operations can be performed using a dedicated joystick or xbox controller.

Connectivity and Scalability

The simulator is prepared to run on various hardware configurations, ranging from a laptop or pc up to a simulator connected to the actual control system console and/or a multi-display solution. Complementary views are offered to display the ROV CCTV cameras, sonar or survey. The 7 function manipulator can be controlled by means of a master arm controller. Optionally, the ROV operations can be performed using a dedicated joystick or xbox controller.

Key features

Interactive environment system

With the VR4MAX environment system you enrich the scene with realistic weather effects for both the sky and the sea. Vary the conditions from a light summer day to a bitter winter storm. The physics engine will react to these weather conditions, the vessel, TMS and ROV will be affected by the waves, current and visibility.

High-fidelity in rendering & physics

When realism and immersion are key, a high-fidelity simulation is critical for success. VR4MAX achieves both with high level graphics performance and integrated AGX Dynamics for world class physics behavior. It allows you to create natural environments that physically interact with every component in it.

Tooling

All tools are fully integrated to be handled by the ROV manipulators or connect with its power supply. Ranging from weights with different handle types to train object manipulation to the Flexi Clean or the TSS-440. The Flexi Clean provides marine growth cleaning capabilities while the TSS-440 allows for cable survey training.

Realistic tether behavior

The quality of the wires in the ROV simulator is exceptional. The tether has been engineered to be a fundamental component in the simulator. The pilot needs to skillfully manage the tether to ensure a good navigation, avoid breaks and be able to dock it smoothly in the tophat Tether Management System (TMS).