Backhoe dredging simulator

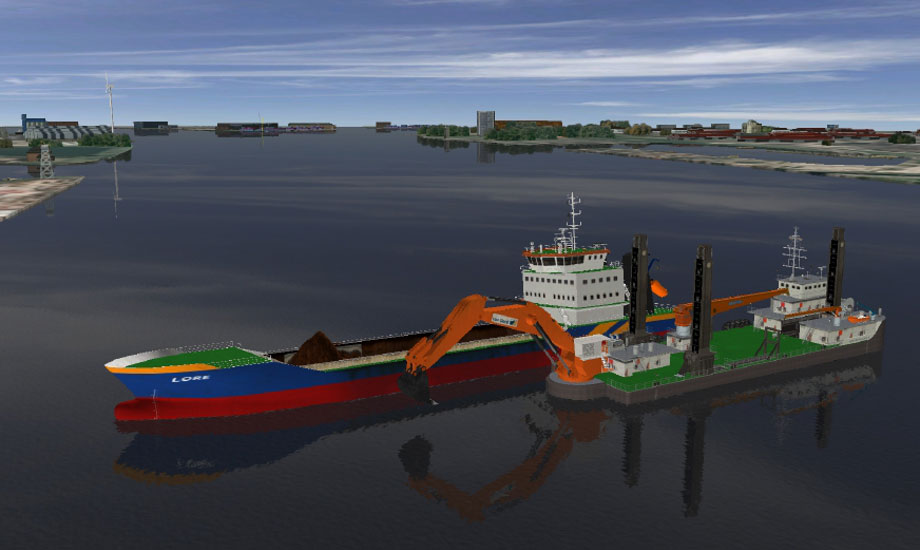

Backhoe dredging simulation

Production efficiency is a key factor for a profitable execution of dredging jobs. Specifically the operation of backhoe dipper dredgers requires skills and experience from the person at the sticks. Correct positioning of the barge, correct bucket angles when removing material, short cycle times, spud handling, adherence to safety regulations it all has influence on a job well done.

With equipment out in the world on operations, a realistic simulator can facilitate this training and have the future crew gain experience in a safe and realistic virtual environment. Tree C does supply such simulators at several levels of sophistication, scalable from a compact laptop-based training setup up to a full functional control chair on a motion base. Our simulators have been validated by experienced people from the field and allow for your own specifications.

Beyond simulation: Real time monitoring

When dredging, visibility of the work site is severely limited because of the turbidity caused by the operation. Based on control system input and real time sensor data the Tree C system generates a ‘’clean’’ virtual representation of the ongoing operation. This provides the operator with valuable feedback to the actual soil displacement and overall efficiency of the operation. Tree C’s monitoring technology can be customized to display various types of operational data.

Key features:

• Realistic VR environment

• AGX based physics simulation

• Advanced soil interaction

• Connect to actual PLCs and controls

• Hardware scalable from laptop to full console with motion base

• Session pause/save/resume

• Custom training scenarios and feedback

• Import actual work site models

• Instructor interface for scenario creation and fault introduction

• Interface available for DipMate and survey systems

Dynamic Soil Simulation

Dynamic Soil Simulation has been added to our Asset Based Simulation Framework.

See our test scene; a Backhoe dredger in action digging virtual soil.

Project Van Oord

Tree C developed a backhoe dredging simulator for Van Oord, The Netherlands. This simulator enables the training of operators in handling the Backacter 1100 backhoe dredging vessel. The real vessel is unique in its size.

The Van Oord simulator includes a large 4 channel projection set-up and a copy of the cabin, including all handling devices, mounted on a motion platform. Van Oord’s extended soil mechanics knowledge is implemented for accurate behaviour of the equipment, which is flexible in its dredge configuration. Alternative sticks and buckets (up to 40 m3) can be selected. The original control system used on the dredger itself is part of the simulator, enabling the experts of Van Oord to develop and experiment with automating the dredging process in a safe simulator environment, and before taking it on board.